How Danish and French Yards Keep Russia's LNG Fleet Afloat

Two Arc7 ice-class LNG carriers at the Yamal LNG project. (Source: Novatek)

Russian LNG continues to flow into Europe at record levels. Two shipyards in France and Denmark provide key dry dock services to keep the Yamal LNG fleet maintained. Since February 2022, 14 out of 15 ice-class LNG vessels in service of the project have traveled to either Damen Shiprepair in France or Fayard A/S in Denmark.

Russia’s Yamal liquefied gas project relies on a fleet of 15 special ice-class liquefied natural gas (LNG) vessels. Two shipyards in France and Denmark play a critical role in servicing and maintaining these vessels.

Since the full-scale invasion of Ukraine in February 2022, Damen Shiprepair in Brest and Fayard A/S in Odense have provided their services to 14 out of the 15 vessels, with eight LNG carriers calling at Brest and seven traveling to Odense.

While the yards’ activities do not violate Western sanctions placed on a multitude of Russian energy projects, they serve as an example of how Europe continues to play an integral part in supporting Russia’s highly profitable and expanding LNG sector.

European countries, especially Belgium, France and Spain, continue to purchase record-level quantities of liquefied gas from Russia. The vessels transporting the product are owned by a mix of companies, including Dynasgas out of Greece and Seapeak Maritime out of Bermuda, the British Overseas Territory.

And with Damen and Fayard two European yards are instrumental in servicing the vessels.

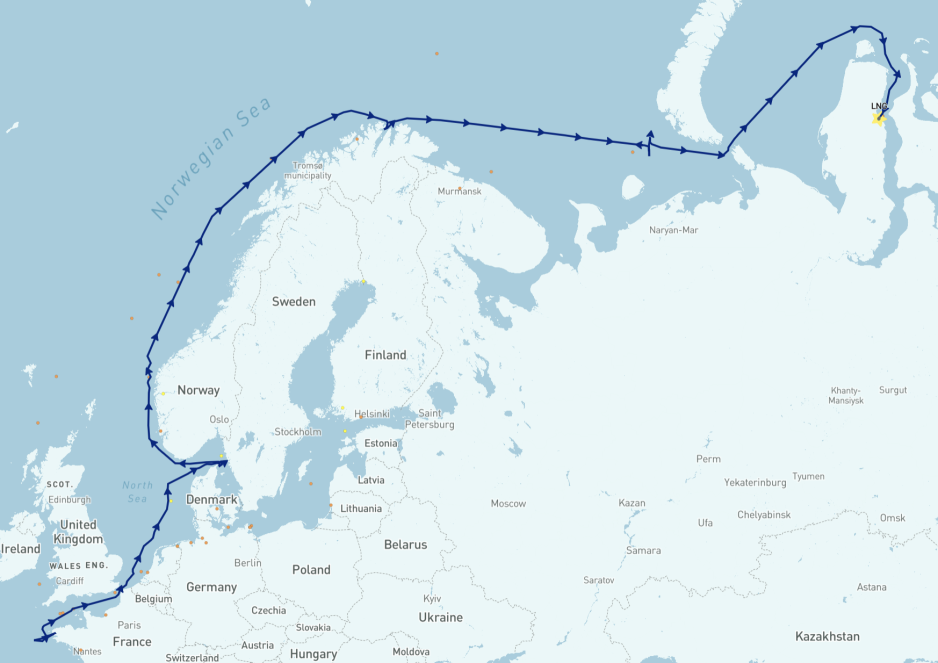

The central location of the Damen and Fayard facilities along the trade route to European markets is key to operating the fleet of purpose-built Arc7 ice-class vessels efficiently. Any detour to yards away from the main travel lanes would quickly become costly for the operators.

“Companies choose the dry docks closest to their transit lines to avoid operating losses. At an average of €100k/day, it is important to optimize dock passage time,” highlights Hervé Baudu, Arctic shipping expert and Chief Professor of Maritime Education at the French Maritime Academy (ENSM).

Privately-owned companies

Damen Shiprepair is part of the Dutch Damen Group, a privately-held shipbuilding, defense, and engineering conglomerate. Fayard A/S, similarly, is a longstanding privately owned Danish company.

In correspondence with HNN, Damen spokesperson Rick van de Weg declined to comment on the issue, advising that the company “never comments on the activities of its client.” He also stressed that Damen has complied with all international sanctions legislation against Russia.

Route of Nikolay Urvantsev returning to service after leaving the Damen yard in Brest in August 2024. (Source: Shipatlas)

Prior to the full-scale invasion of Ukraine Damen operated an engineering branch in Russia. It scrapped a number of shipbuilding contracts following sanctions restrictions imposed by the Dutch government and is currently seeking compensation from the government for lost business.

The company’s former business with Russia includes the delivery of dredging equipment, a Damen Cutter Suction Dredger (CSD) 450, used for work with Russia’s Arctic LNG projects, just days before the invasion of Ukraine.

French and Danish yards are key partners

Damen’s Brest facilities completed dry dock work on four Yamal LNG carriers in 2022, three in 2023, and at least one in 2024. The company declined to confirm the accuracy of HNN’s research based on vessel tracking sites using AIS data.

Satellite image of Nikolay Urvantsev at Damen yard in July 2024. (Source: Planet.com)

The following ice-class LNG were serviced in Brest since February 2022: Vladimir Voronin (July 2022), Georgiy Ushakov (August 2022), Yakov Gakkel (August 2022), Eduard Toll (September 2022), Rudolf Samoylovich (June 2023), Vladimir Vize (September 2023), Nikolay Yevgenov (October 2023), and Nikolay Urvantsev (July 2024).

An additional three vessels from Russia’s LNG fleet called in the period from 2019 and 2021.

Danish Fayard A/S did not respond to requests for comment. The yard has been providing services for the fleet of Yamal carriers going back to at least 2020, vessel tracking data show.

Over the past four years 14 LNG carriers have been serviced at its facilities, with some vessels recording more than one visit.

In the time since February 2022, seven vessels were dry docked at Odense, which include: Nikolay Urvantsev (May 2022), Boris Vilkitsky (August 2022), Fedor Litke (September 2022), Vladimir Rusanov (October 2022), Boris Davydov (August 2023), Nikolay Zubov (October 2023), and Vladimir Voronin (July 2024).

Vessel tracking data for 2024 show one visit so far during July of this year, though the majority of yard work has historically been carried out in the Fall, indicating that additional vessels may yet follow.

Satellite image of Vladimir Voronin at Fayard A/S yard in July 2024. (Source: Planet.com)

The location is key

In speaking with shipping industry experts they explain that the choice of shipyard depends on three main criteria: the size of the dry dock, its availability, and the type of working needing to be carried out.

For example, in France there are three dry docks able to accommodate very large tankers of the size of the Yamal LNG carriers. The facilities are located at Brest, Saint-Nazaire and Marseille.

The yard at Saint-Nazaire has limited availability as it specializes in ship construction, not maintenance. Marseille, in the Mediterranean, would mean at least a week’s detour roundtrip for the vessels, which do not usually operate in southern Europe.

This leaves Brest, ideally located along the vessels’ main trade route between the Arctic and western Europe.

“The dry dock in Brest specializes in repairs, but above all in hull maintenance. Its main advantage is that it is on the transit route between Yamal LNG and Montoir-de-Bretagne, where the Arc7s come to unload. A stay to the dry dock for routine maintenance can last from one week to 10 days,” explains Baudu.

Some of the LNG vessels recorded even longer yard times, up to 25 days, HNN data show, when damage sustained during Arctic operations requires unplanned repairs. In December 2019, for example, Georgiy Brusilov traveled to Brest for work on its gas containment system.

While Brest does not perform a lot of heavy engine repairs, it does specialize in hull maintenance, the type of work the LNG carriers require regularly operating in harsh Arctic conditions.

“The Arc7s come to Brest mainly to carry out their so-called "five-yearly" technical inspection. This involves inspecting the hull valves, dismantling them, and repainting the hull,” explains Baudu.

The central location of the yards in Brest and Odense is key to operating the Yamal fleet efficiently.

The availability of European yards, in Brest, Odense, or elsewhere in the region, help keep Russia’s LNG operations afloat. They allow Russia to maximize the use of its specialized fleet to carry Russian LNG to markets, industry experts conclude.