Up to Nine Million Tons of Russian LNG Will be Reloaded in Norwegian Waters during 2019

An LNG carrier of the Norwegian coast in winter. (Source: Courtesy of Torbein Rønning on Flickr.com under CC BY-NC-ND 2.0). // LNG-lasteskip ved norskekysten vinterstid. (Foto: Torbein Rønning/Flickr)

Norwegian shipping company Tschudi plans to transship up to 9 million tons of LNG during the first six months of 2019. A substantial operation would reload natural gas from Novatek’s Yamal facility on average every 36 hours.

The Norwegian Coastal Administration (Kystverket) released new information about the location, duration, and scope of Tschudi’s ship-to-ship transfer operation of liquefied natural gas in cooperation with Novatek’s Arctic Yamal project. According to regulatory documents the transshipments will be conducted in the Sarnesfjord and Outer Kåfjord area in the Nordkapp municipality, to the south-west of Honningsvåg. Operations are expected to begin before the end of the month and the company expects to reload up to 140 shipments between November 2018 and June 2019, or on average one every 36 hours.

Tschudi Arctic Transit (TAT), a subsidiary of the Tschudi Group, will conduct up to 16 reloading operations in 2018 and 21 each month between January and June 2019. Each shipment will consist of around 80,000 tons of liquefied natural gas (LNG). Novatek’s Yamal LNG plant can produce up to 16.5 million tons of LNG annually. The permitted number of 140 shipments would be sufficient to reload the production output of the facility during the first six months of 2019. Neither Novatek nor Tschudi have made any public statements about their plans for the operation.

As High North News reported earlier this week, the gas will be transferred from ice-capable Arc7 vessels to conventional LNG carriers. This allows Novatek, which faces a shortage of ice-capable LNG carriers, to maximize the use of these specialized vessels and operate them exclusively on the ice-covered waters of the Northern Sea Route.

LNG Transfer 500 meters from shore

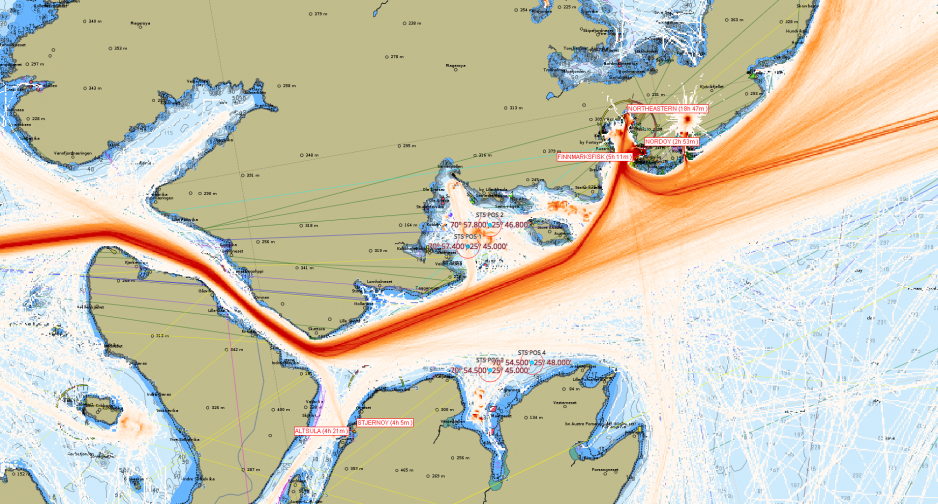

The regulatory documents show that four ship-to-ship transfer (STS) areas will be established. Transshipment Areas One and Two are located in Sarnesfjord, which is well sheltered from wind and weather and has a wide entrance – at least five nautical miles at its narrowest point. Similarly, Areas Three and Four, in the Outer Kåfjord, are easily accessible but are somewhat less sheltered from wind and weather.

Kystverket map showing STS Positions One and Two to the west of Honningsvåg and Positions Three and Four to the southwest. (Source: Courtesy of Kystverket). // Kystverkets kart viser STS’ omlastingsområde en og to vest for Honningsvåg, og område tre og fire lenger sørvest. (Illustrasjon: Kystverket).

TAT will be permitted to use three out of the four STS areas simultaneously, with the two areas in Sarnesfjord given priority. The Kystverket requires that the two areas in the Sarnesfjord be used first, unless wind and wave direction favor the locations in Kåfjord.

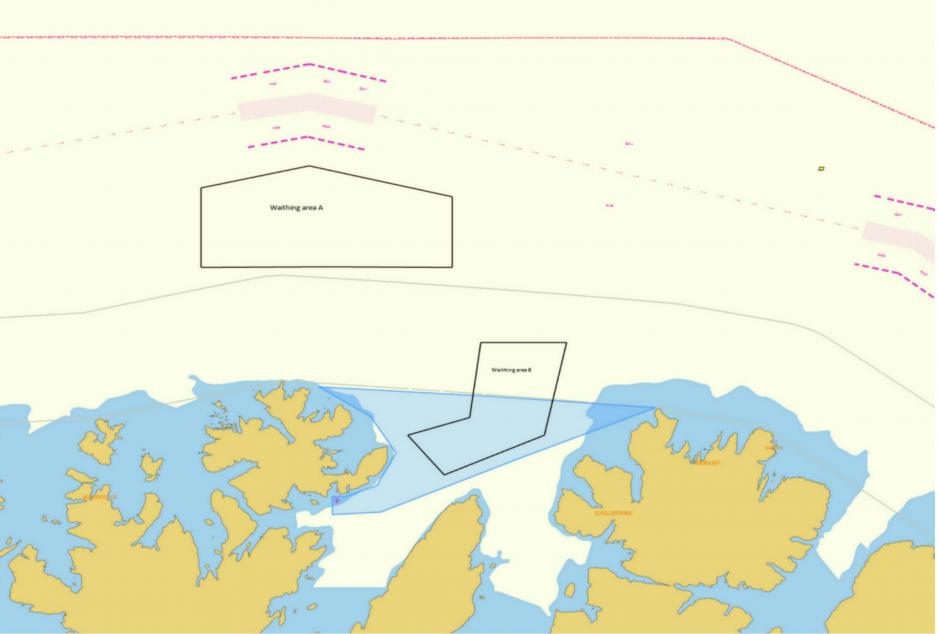

If the transshipment areas are occupied, arriving vessels have to hold in two waiting areas away from the coast, until they can enter one of the four the reloading areas. Area A will be for vessels with a wait time over 12 hours and Area B will be for vessels with fewer than 12 hour. Both areas are off Magerøya and between five and 20 nautical miles off the coast.

Waiting Areas A and B to the north and northeast of Honningsvåg. (Source: Courtesy of Kystverket). // Venteområdene A og B nord og nordøst for Honningsvåg. (Illustrasjon: Kystverket)

Extensive safety precautions

During transshipment operations one out of the two vessels has to lie at anchor, both guarded by a stand-by tug and a safety vessel. No reloading operations may occur when solid or broken ice, icebergs, or any other form of sea ice is present within one kilometer of the transshipment site. The vessels also have to be surrounded by floating oil barriers and oil spill equipment sufficient in capacity to vacuum spills from the vessel’s largest oil tank must be on site and ready to be used within 20 minutes. A second such system has to be deployable within one hour of an accident. These safety measures are applicable for each individual reloading operation and each simultaneous transshipment operations is required to have independent preparedness equipment.

The Norwegian Directorate for Civil Protection (DSB) conducted a number of assessments related to the application, including a risk analysis, procedure for reloading, contingency plan, etc. Meetings were held with local stakeholders, including the Nordkapp municipality, fire department, municipal planners, and the harbor masters.

For the purpose of staffing and equipment needs TAT will enter into an agreement with a company called “LNG STS.” Some crew will be housed locally. DSB emphasized the importance of clear procedures for loading and unloading and proper coordination and communication between TAT and LNG STS. This includes a full-scale emergency response test, which has to take place before the start of operations and has to be repeated at least once a year. A two-week notice has to be given before the test.

The permit requires hoses used for the transfer of LNG to contain emergency disconnect functions and vessels have to be ready for immediate departure from the area in case of an accident. Furthermore, in accordance with regulations by the International Maritime Organization in order to reduce the environmental impact on coastal waters 95 percent of ballast waters have to be replaced before the ship arrives at the transshipment site.

Kystverket showing the busy shipping lanes around Honningsvåg in relation to the four approved LNG transshipment areas. (Source: Courtesy of Kystverket). // Kystverket viser de travle skipsledene rundt Honningsvåg i forbindelse med de fire godkjente LNG-omlastingsområdene. (Illustrasjon: Kystverket)

Changes to the original permit

Tschudi’s initial permit dates back to 2007 when the company had applied for permission to transship gas condensate in the same geographic area. The permit was subsequently renewed in 2013. A request to add the reload of LNG to the permit was received by Kystverket on August 13 and permission was granted on October 2, the documents show.

The original permit allowed for two simultaneous transshipments. This was increased to three under the altered permit. This was in part justified with LNG having lower potential for damage in case of emergency spills, compared to gas condensate, gasoline and crude oil.

Kystverket also highlights that the original permit is ten years old and will have to be renewed in 2019. For this TAT will need to prepare an updated risk and environmental impact analysis.