Life on the Arctic Coast: Raimo (45) Manages one of Norway's Northernmost Fish Plants

Kjøllefjord, Northern Norway (High North News): Raimo Sørensen started working at the fish landing in Kjøllefjord just over 20 years ago. Today, he manages the facility, which is located in the far north of Finnmark – and in which Lerøy is now investing NOK 158 million.

When Raimo Sørensen (45) started his professional career at the end of the '90s, he processed fish at the fish landing in Kjøllefjord – one of Norway's northernmost fishing villages.

Today, he is site lead at the facility that Lerøy Norway Seafoods now owns.

"It has been a few years now, yes. When you work a while in the fishery industry, you often get more responsibility. At the plant, I have been head of all the departments, apart from the technical department," says Raimo to High North News.

For the factory manager, the fishing industry is also part of his roots, with a father who worked on the fish processing plant – and a mother from Finland who traveled to Kjøllefjord to work in the fishing industry.

"A product of the foreign worker who has always come here," says Raimo.

We meet him on a Monday in late October. Above the mountains and plains, it is entirely white. It is sunny and cold in the air, and the Kjøllefjord is quiet.

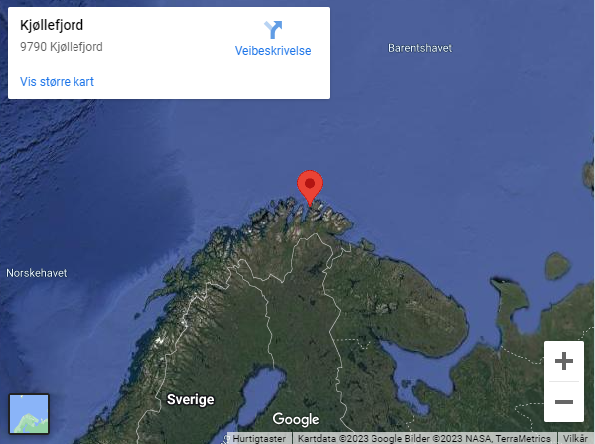

The town of Kjøllefjord is located in Lebesby municipality, on the west side of the Nordkinn Peninsula in the northernmost part of Norway.

Located on the large islands to the west are the towns of Nordvågen, Honningsvåg, and Nordkapp, among others. By the cliffs to the east along the coast of Finnmark, we find Mehamn, Gamvik, Berlevåg, Båtsfjord, and Vardø.

The fishing town is located in the innermost part of the fjord, but nevertheless, we are, so to speak, completely out in the Barents Sea.

From Kjøllefjord to the US

The fish processing plant in Kjøllefjord is referred to as Lerøy's red king crab center. All crab landed in East Finnmark is sent to this facility for further processing. Last year, the volume was around 400 tonnes.

From here, the red king crab is exported to the world either frozen or cooked, fresh or alive, says Raimo. The primary market is the USA. American customers have had the greatest willingness to pay in recent years. There, the king crab often ends up on the dinner table at various restaurants.

The USA is the largest export market for Norwegian red king crab in general. This year, the Americans bought this type of crab for NOK 308 million – a significant development from NOK 162 million last year. After the USA comes Hong Kong and then South Korea.

Since 2014, the export value of king crab has also increased considerably. Norway sold red king crab for NOK 132 million then. So far this year, the figure is NOK 902 million, according to the Norwegian Seafood Council.

No one has crab as good as Lerøy Kjøllefjord, says Raimo. "Our process gives a very special and good taste," he says.

Aims for year-round jobs

There are around 26 permanent employees at the facility. Raimo says that many of the employees originally come from abroad, mainly Lithuania and Poland. But most of them live in Kjøllefjord all year round. In addition, there will be more to keep the wheels turning in peak seasons.

"Year-round jobs are the key to getting people to settle down. If you can offer a permanent job all year round, people will settle – but it can be challenging," says Raimo and refers, among other things, to the fact that the availability of fish and crab has a lot to say in this context.

Raimo also praises Lebesby for the services the municipality works for, especially when it comes to schools and kindergartens. At the same time, he highlights other challenges of living in the district, such as having to send new employees far away for necessary tasks in the middle of winter during a hectic winter season.

Listen to Raimo talk about some of the challenges the company might face when operating in the district. (English subtitles are available).

"The key word is processing"

While red king crab makes up around 30 percent of the production at Lerøy Kjøllefjord, the facility also produces salted fish and fillets of white fish such as cod, haddock, and pollock.

"We have a great range in what we do. The key word is processing."

"Processing crab is an important supplement to the activity, and it contributes to jobs. But we also pack whitefish at the plant, for example," he elaborates.

The Lerøy plant relies on raw materials from a varied fleet. One of these is the fishing boat "Tinder," which comes into the fjord while we are talking on the quay.

The vessel docks at the fish plant. On board, captain Daniel Lauritzen from Kjøllefjord has large quantities of fresh haddock with him – about 2.5 tonnes of fish.

Crate upon crate with haddock is loaded onto the quay, where it is driven away by a truck into the plant.

The fish delivered here probably has one of Norway's longest – and most demanding – journeys to the market in Europe.

"The trailer drivers who transport the fish use about two days down to Denmark. If we send the fish on Friday, customers in France will have it on Monday," says the factory manager, adding:

"The trailers go over the mountains, and there are often challenges. The logistics are complicated, but Thermo-Transit makes it happen. They have skilled and tough drivers who make the trip up here to the Nordkinn Peninsula."

The red king crab from Kjøllefjord is transported either by plane or ship, depending on whether it is sent fresh, alive, or frozen. In recent years, however, less fresh crab has been exported, says Raimo.

Figures from the Seafood Council also show that Norway has not exported fresh/chilled king crab so far this year. Most Norwegian exports of king crab are live, while some are also sent frozen.

You don't invest 158 million if you're going to disappear tomorrow.

Invests 158 million

When Lerøy took over the plant in 2016, the company invested NOK 20 million in a new cooking facility at the plant. Now the group is multiplying the sum and making a new and larger investment in the factory.

A short time ago, Lerøy decided to invest NOK 158 million in the plant. The work itself will start in 2024, and then, among other things, the landing section, which dates from the 1950s, will be demolished and rebuilt.

New production equipment will be installed, and the investment will increase capacity at the facility.

"The aim of the investment is to make us more equipped for the future so that the plant can develop further."

Raimo Sørensen from Lerøy Kjøllefjord talks with HNN's journalist Hilde Bye about Lerøy's investments in the facility. (Subtitles are available in English).

Signals that they are staying

According to Raimo, there will be some automation in the new investment, but not very much.

"There is still room for people. But if you can make changes to the work that puts the most strain on people and automate such things, then I see that as a good thing," he says and continues:

"I think it is better to use a man or woman in another area, which are even greater contributions, instead of doing unnecessary operations."

"This is an industrial boost for us. The decision is also a signal of staying put; you don't invest 158 million if you are going to disappear tomorrow," he concludes.

This article is part of High North News' series of articles on life on the Arctic Coast. Feel free to share your tips with our journalist, Hilde Bye.