Freyr Stops Battery Production and Lays Off Employees

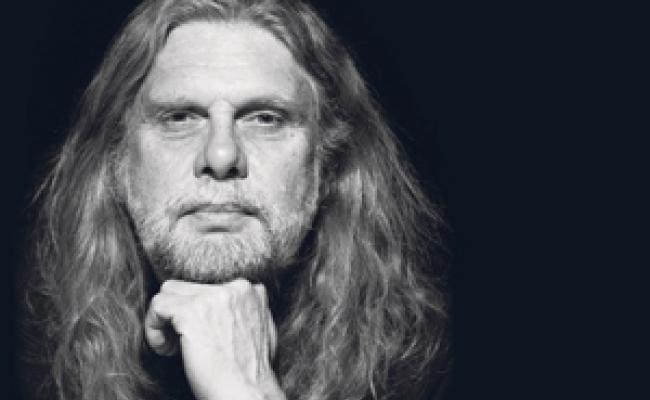

CEO of Freyr Tom Jensen presented the battery factory during the High North Dialogue in Bodø in 2019. Due to stiff competition from China, the battery company must lay off several employees and conduct a "significant downscaling." (Archive photo: Trine Jonassen)

The battery company Freyr must lay off several employees and make "significant downsizing." The production of battery cells in Mo i Rana is now put on hold.

The article has been updated.

In August, Freyr employees were notified that the battery company must significantly downscale in order to adapt to new market conditions for battery cells within the battery industry.

"Sadly, we must reduce the number of employees in the company to ensure financial runway for the company," says the CEO of Freyr Battery, Tom Jensen, to Rana Blad.

Freyr has about 60 employees in Mo i Rana in Northern Norway, and about 180 in total. Jensen informs that the most significant reduction will be in Mo i Rana.

Stopped by China

Jensen highlights that Freyr will still have employees in Mo i Rana and that the company still considers the city the best place in Norway for battery production.

One of the biggest challenges that Freyr is facing is the low prices of battery cells produced in China.

According to Tom Jensen, this makes it harder to compete with Chinese producers, particularly if customers are unwilling to pay more for products produced in Norway.

Freyr will focus on research and development in the pilot factory

Must act now

In an email to High North News, Jensen states that Freyr must act now to ensure long-term stability.

"Freyr will focus on research and development in the pilot factory, modular packaging of batteries using surplus battery cells , as well as digital battery solutions".

Adding to a comment in The Economist, Jensen tells High North News that he believes the only way Western battery companies will be able to compete without the above solution is through new and better implementation of new technologies.

Paused

In November last year, the company also had to cut back. 78 employees were laid off, ten of whom worked at the factory in Mo i Rana. The original plans with a giga factory included a staff of 1,500 in Mo i Rana alone.

Last year, it was revealed that Freyr would "pause" the construction of the Giga Arctic factory in Northen Norway, which was supposed to produce batteries of industrial size.

Frey's pilot factory in Mo i Rana. (Photo: Phillip Navin)

Freyr has built a pilot factory in Mo i Rana, as well as a large building intended for gigafactory cell production, Giga Arctic, where 86,000 m2 of a total plan of 146,000 m2 has been built today.

Massive support

According to NRK, Freyr now plan to use the pilot battery factory to pack several batteries into a larger battery that can produce a higher voltage or deliver more power, among other things.

Freyr has received 200 million in government support for the development of the pilot factory and detailed planning of Giga Arctic as well as a digital battery platform for the development of batteries, and far more in loan guarantees, which can be used in a longer perspective given the full investment and realization of Giga Arctic.

In 2023, it was reported that former CEO Tom Einar Jensen had received a salary and bonus of a total of NOK 27 million for 2021.

In 2022, the board received a total remuneration and share options with a total value of over NOK 60 million. However, Freyr states that the value of the shares has fallen since 2022.